Route Planning Software

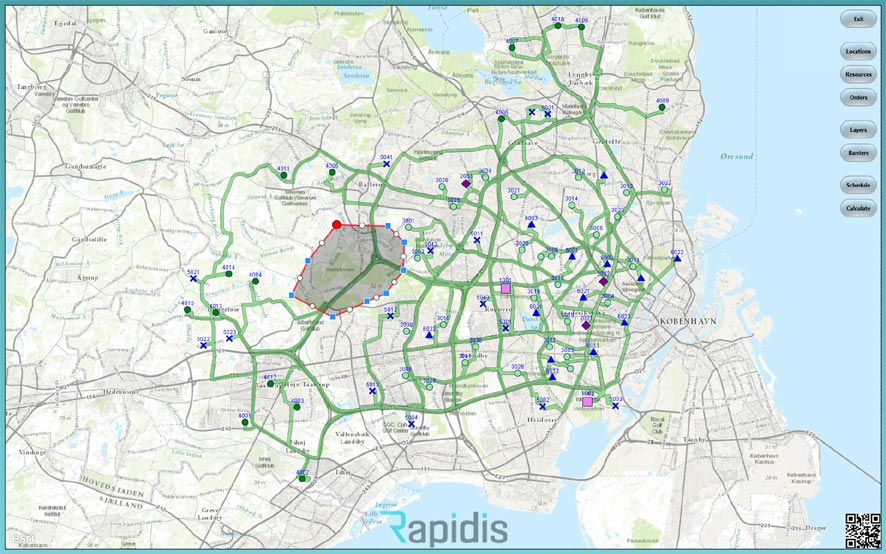

Rapidis develops software for Route Planning and optimization; Rapidis Logistics Planner (RLP) that offers Route Planning for several industries and purposes.

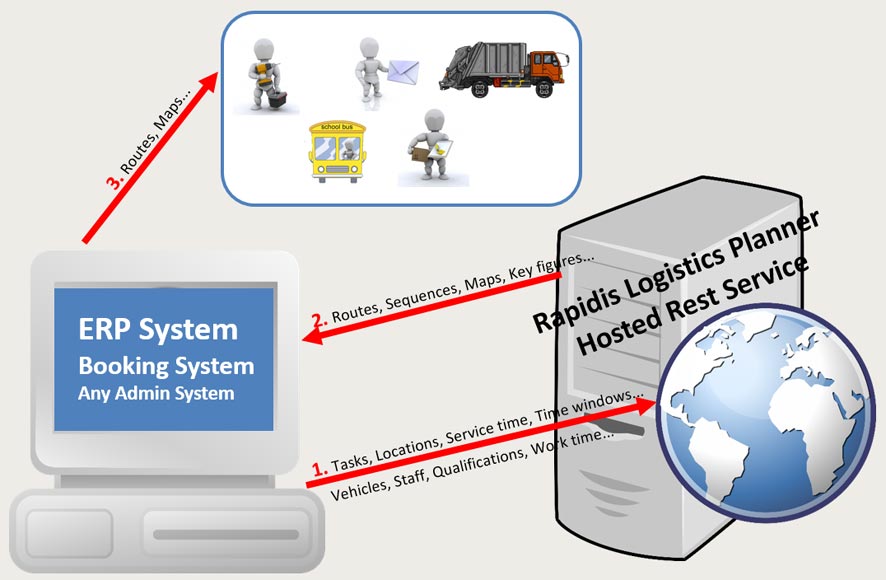

The Route Planning is available as a cloud hosted web service, SaaS, and as extensions for Esri ArcGIS. If you are looking to add route planning and optimization to your current IT system you can do so with our SaaS offering.

Rapidis Logistics Planner is available in 3 different editions each with specific capabilities in several industries. Take a look at our route planning references and learn how the 3 editions are used to solve real life route planning problems.

Rapidis offer free trials. Please click the green button or Leif Dahl Petersen for more information.

High Density Route Planning

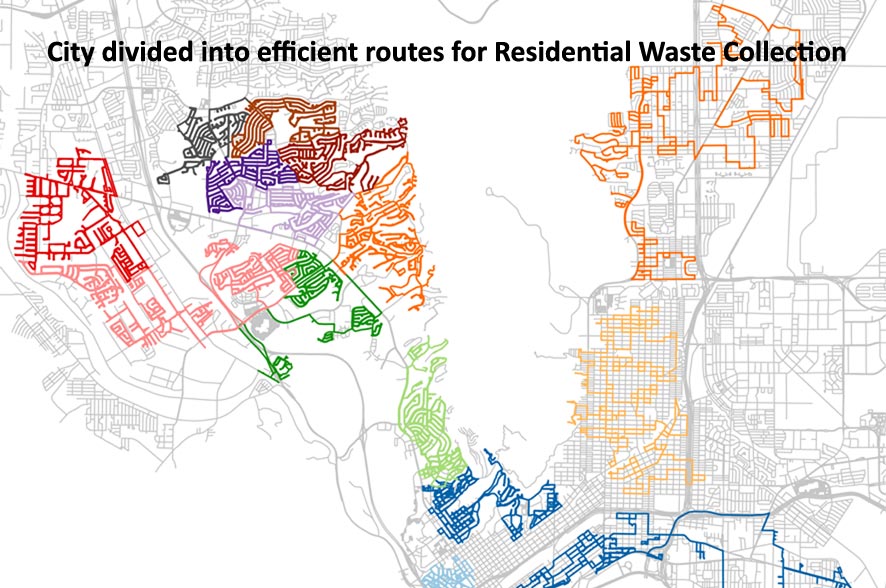

Software for Route Planning scenarios where you want to visit all (or most) addresses in a area like a city og a municipality. This could be for postal delivery routes for mail or newspapers or total market coverage with printed advertisement material or it could be for pick-up routes for residential waste collection.

The vast number of addresses would normally make it very time consuming and perhaps impossible to create an OD cost matrix with drive-time from all-to-all addresses. Therefore, the High Density edition of Logistics Planning has tools for grouping or clustering of addresses and this will make the it possible to solve the route problem.

Postal routes and newspaper routes are often served by carriers either walking or using a bicycle. In order to plan and optimize walking routes the software automatically produces a sidewalk network which is bi-directional and allows for the planner to decide walking speed. Routes served by cars are calculated on a traditional street network.

The edition for High Density route planning includes tools both to divide a group of addresses into efficient routes and another tool to optimize the sequence for existing routes. The tools can be utilized in combination or one at the time depending on the route optimization scenario.

Pickup and Delivery Route Planning

This edition is for route planning where all orders have both a pickup and a delivery on the same route. Rapidis has developed functionalities dedicated for Demand Responsive Transport (DRT) like medical trips, paratransit and school bus routing.

This objectives for route planning and optimization in DRT is to combine pairs of pickups and deliveries in order to minimize total costs for the fleet and, at the same time, ensure that all restrictions and constraints are respected.

Route planning and scheduling for DRT is different from other industries. We want to favor schedules with high passenger convenience. Also we need special functions for restrictions and constraints to ensure that the route planning can handle objectives like “who can travel together at the same time – and who can not?” or “this passenger needs to be driven by a chauffeur known to him.”

Vehicle Routing Problem

Software for last mile route planning like parcel distribution, inspections and service tasks.

The route planning software will help you make the best over-all plan for a fleet of vehicles minimizing total costs and ensuring that all restrictions and constraints are met.